Visual & Thermal Inspection / Monitoring of Wind Turbine Blade

Using modern innovative drone technology, Visual Inspector collects visual data 40% more as compared to conventional scaffolding method. It avoids the need to climb infrastructure or rope access. It prevents your asset inspectors being put at risk. We performed inspection with Visual and thermal camera along with advanced NDT includes thorough assessment of blade condition, tower weld integrity, composite materials. Shyenaksha Inspection advanced drone technology offers wind turbine inspection and reporting solutions allow for faster, safer, and more accurate site inspections.

Visual & Thermal Inspection of Chimney

Shyenaksha Inspection offers weld inspection and surface monitoring with visual and thermal camera under our NDT experts (ASNT Level III, ACCP Level III, ISO 9712 Level 3, AWS).

Visual & Thermal Inspection / Monitoring of Infrastructure

We provide accurate comprehensive knowledge, Non-Destructive (NDT) solution and information about structural steel bridge, Fabricated metal structure, material properties, defects, structural condition, integrity that assists effective asset management, and safety. Shyenaksha Inspection has extensive expertise in the assessment of materials including steel, cables, composites and damage such as corrosion, cracking. Shyenaksha Inspection offers 2D/3D view of structures, asset which will enhance the inspection and monitoring with the help advanced visual camera. It avoids the need to climb infrastructure or rope access. It prevents your asset inspectors being put at risk..

About us

Visual & Thermal Inspection / Monitoring of Storage Tank

We offer best leak, corrosion detection in less time with thermal inspection and monitoring Insulated Tank For CUI.

About us

Visual & Thermal Inspection of Transmission Tower

Asset integrity and condition inspection and condition assessments using advanced drone’s technology is now an essential tool for monitoring power line and transmission and distribution networks. Shyenaksha Inspection use state of the art advanced camera and drone technology to inspect all essential components of transmission and distribution network assets. Shyenaksha Inspection can identify deteriorating and defective cross members, bolts, phase conductors, gussets, insulators, ground wires and other poor performing components maintaining unique angles and a safe distance. Using modern equipment’s for power line and transmission infrastructure inspections is fast and safe. It avoids the need to climb infrastructure or rope access. It prevents your asset inspectors being put at risk. Get advanced warning of components that are at risk of capacitor breakdowns with the use of radiometric infrared thermal cameras. Shyenaksha Inspection radiometric infrared thermal inspections and monitoring can detect differential heating of components to quickly highlight components of concern. Defect analysis is conducted by experienced engineers and communicated to asset managers though detailed reports and 3D digital platforms.

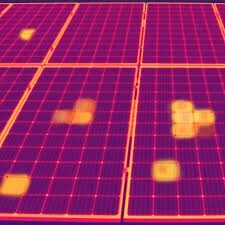

Visual & Thermal Inspection of Solar Panels

Shyenaksha Inspection offers solar farm inspection solutions allow for faster, safer, accurate site inspections. The unique perspective of low altitude aerial data capture with advanced visual as well as radiometric thermal camera offers solar energy providers with valuable, actionable information to maintain the plant at optimum productivity. Successful radiometric thermography (thermal imaging and analysis) depends on the operator’s understanding of the principles of emissivity, heat transfer and their application in the field in which they are working. That’s where Shyenaksha Inspection can help. Now, with the ability to study images from the air, thermal infra-red imaging is becoming a powerful tool in asset inspection. Shyenaksha Inspection detect faulty solar panels, solar modules, solar cells and monitor voltage balance, overload or over-voltage which effects efficiency to power generation.

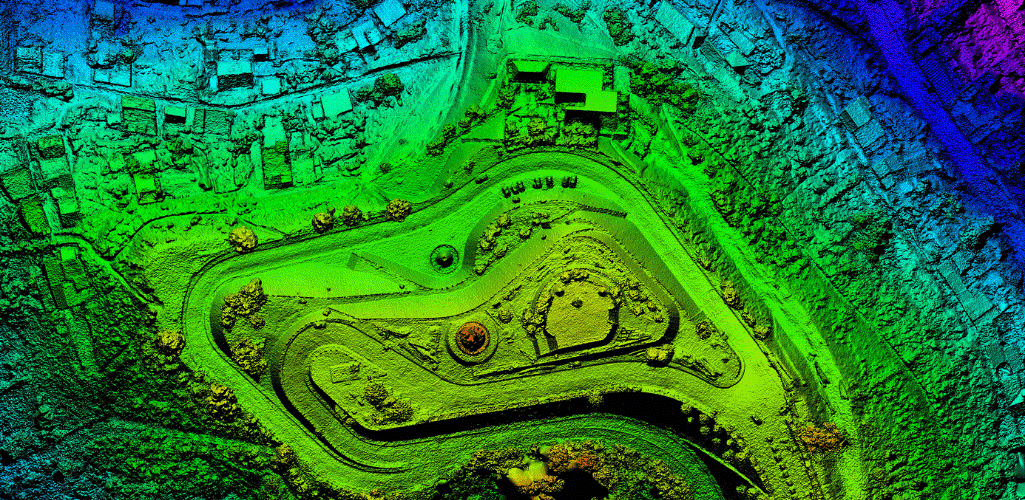

Aerial Survey

Shyenaksha Inspection survey and mapping teams collect aerial imagery of the landscape and turn it into actionable information to improve land management and stewardship. Our advanced drone technology offers topographic surveys of the same quality as the highly accurate measurements collected by traditional methods, but in a fraction of the time. This substantially reduces the cost of a site survey and the workload of specialists in the field. Our advanced drone camera produces crystal-clear video, still images, radiometric thermal imagery. All imagery is captured digitally, and transmitted in real-time to inspection teams located on the ground. Shyenaksha Inspection use the principals of photogrammetry to produce accurate 2D/3D models of infrastructure and landscapes that seamlessly integrate with existing Building Information Modelling (BIM) systems. Allowing asset managers to have confidence that no management concerns are missed.

Thinkness Guaging

Non-Destructive Testing (NDT) covers a range of techniques that assess the quality of a component without causing damage to the part / surface. Shyenaksha Inspection offer thickness measurement with advanced robotic crawler using ultrasonic thickness measurement. Our advanced robotic thickness measurements provide 360 degrees reading and travel in any axis and reduce the human error while taking thickness measurement which will be controlled by our NDT experts. It avoids the need to climb chimney or structure. It prevents your inspectors being put at risk .

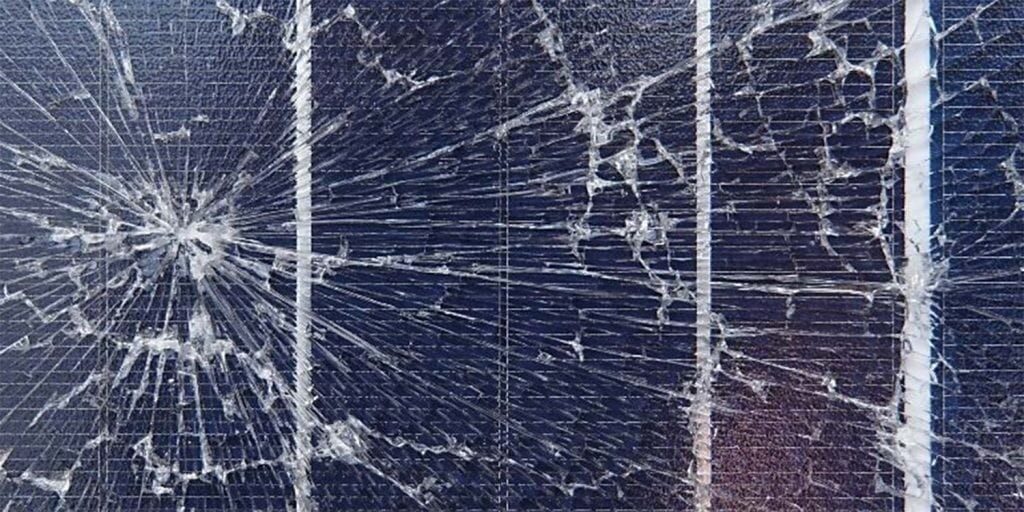

Robotic Solar Panel Cleaning

Shyenaksha Inspection offers advanced robotic solar panel cleaning to increase the efficiency of photovoltaic system. It will reduce the human intervention in cleaning of solar panel and time with cost.

Robotic Wind Turbine Blade & Tower Cleaning

“Revolutionizing Wind Energy: Robotic Precision for Cleaner Blades and Towers”

Drone Technology for Railway Projects

Shyenaksha Inspection LLP harnesses cutting-edge drone technology for comprehensive railway inspection, monitoring, and maintenance, ensuring operational efficiency, safety, and proactive infrastructure management. Our use of high-resolution imaging and advanced thermal sensors provides precise, real-time insights for effective decision-making.

Key Services for Railways

1. Railway Track Monitoring:

Detection of track defects and obstructions

Identification of unauthorized activities near tracks

2. Bridge and Structural Inspections:

High-resolution inspection of railway bridges for cracks, corrosion, and structural integrity

Detailed 2D and 3D mapping for maintenance planning

3. Station Facility Assessments:

Monitoring station layouts for operational efficiency Inspection of station roofs, platforms, and other infrastructure

4. Yard and Siding Surveillance:

Monitoring rolling stock and assets in large yards

Enhanced security through real-time surveillance

5. Disaster Response and Recovery:

Immediate aerial assessment during derailments or accidents

Quick data acquisition for faster recovery and restoration

Drone Technology for Railway Projects

Shyenaksha Inspection LLP harnesses cutting-edge drone technology for comprehensive railway inspection, monitoring, and maintenance, ensuring operational efficiency, safety, and proactive infrastructure management. Our use of high-resolution imaging and advanced thermal sensors provides precise, real-time insights for effective decision-making.

Benefits of Drone-Based Railway Inspections:

Enhanced Safety: Minimizes the need for manual inspections in hazardous locations.

Cost Efficiency: Reduces operational downtime and lowers inspection costs. Time-Saving: Faster data collection compared to traditional methods.

Accurate Data: High-quality imaging for precise analysis and decision-making. Enhanced Safety: Minimizes the need for manual inspections in hazardous locations.

Cost Efficiency: Reduces operational downtime and lowers inspection costs. Time-Saving: Faster data collection compared to traditional methods.

Accurate Data: High-quality imaging for precise analysis and decision-making.

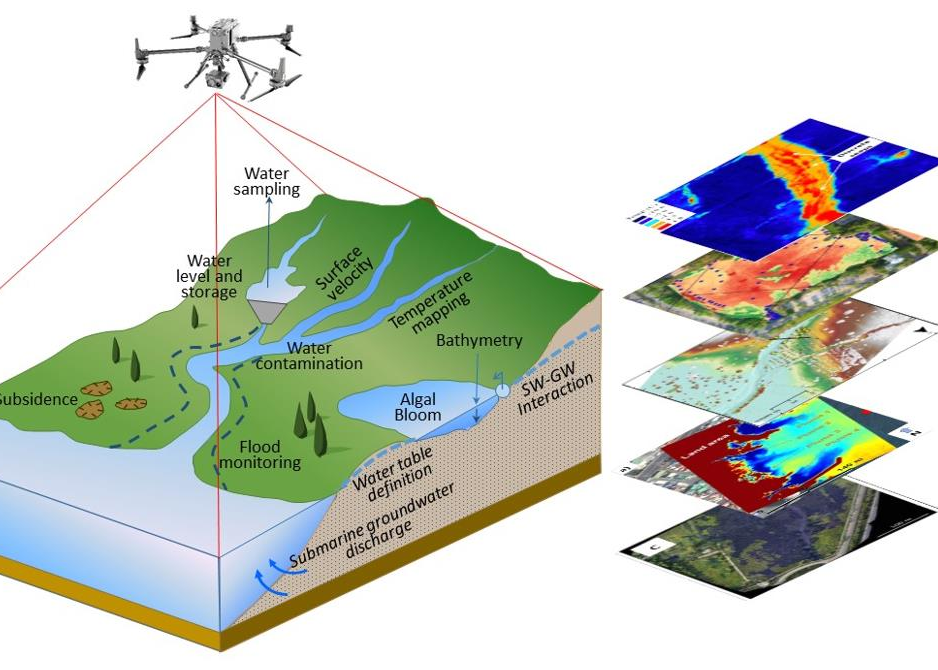

1. Dam Inspection and Maintenance

Shyenaksha Inspection specializes in providing cutting-edge drone-based solutions tailored for irrigation and water resource management. Our services enhance the efficiency, accuracy, and sustainability of water infrastructure projects.

Visual and Thermal Assessments: Utilizing high-resolution cameras and thermal imaging to detect leaks, cracks, and structural anomalies in dams.

Spillway Analysis: Monitoring sediment accumulation to ensure optimal water flow and storage capacity.

Structural Mapping: Creating detailed 2D and 3D models of dam infrastructure to facilitate maintenance planning.

2. Canal and Pipeline Surveys

Aerial Surveillance: Conducting comprehensive aerial surveys to identify blockages, leaks, and areas requiring maintenance in canals and pipelines.

Thermal Imaging: Employing thermal sensors to detect temperature variations indicative of leaks or inefficiencies.

Digital Mapping: Developing precise maps for infrastructure planning and rehabilitation projects.

3. Embankment Stability and Flood Management

Structural Integrity Analysis: Assessing the stability of embankments and identifying vulnerable sections prone to erosion or failure.

3D Terrain Modeling: Generating detailed topographical models to aid in flood risk assessment and management strategies.

Sediment Management: Analyzing sediment deposition patterns to inform dredging and maintenance activities.

4. Reservoir Sedimentation Analysis

Digital Elevation Models (DEM): Creating accurate representations of reservoir beds to measure sediment accumulation and assess storage capacity.

Capacity Restoration Planning: Providing data-driven insights to support sediment removal and reservoir rehabilitation efforts.

5. Command Area Development

Agricultural Land Mapping: Surveying irrigated areas to optimize water distribution and enhance crop yield.

Irrigation Planning

Assisting in the design of efficient irrigation systems, including drip and sprinkler setups, to promote water conservation.

Soil Moisture Analysis: Utilizing advanced sensors to monitor soil moisture levels, aiding in precise irrigation scheduling. — Advantages of Drone Technology High-Quality Data Acquisition: Drones capture detailed and accurate information, surpassing traditional survey methods.

Time Efficiency: Rapid deployment and data collection reduce project timelines. Cost-Effectiveness: Lower operational costs compared to conventional inspection techniques.

Enhanced Safety: Minimizes the need for personnel to operate in hazardous environments. Real-Time Monitoring: Provides immediate insights for prompt decision-making, crucial during emergencies.

—

Shyenaksha Inspection is committed to delivering professional and reliable drone services to support the sustainable development and maintenance of water resource infrastructure. Partner with us

to leverage technology for smarter water management solutions.